| |

The invention provides an improved method and apparatus for making viscous

mixtures accessible to Separation by solvent extraction by means

of dispersion. The present invention further provides a method for

preparing a dispersion. This object and others which will become

apparent as the specification progresses, are accomplished by the

invention, according to which, briefly stated, a mixture to be treated

is charged with a solvent and then sprayed to form a dispersion,

which is e.g. thereafter subject to Separation. The method comprises

charging a viscous mixture with a liquid or gaseous solvent and

spraying the homogenous solution to form a dispersion, contacting

said dispersion with a solvent for at least one component of the

mixture, dissolving at least one component of the mixture in solvent,

and separating the solvent containing at least one component from

the remaining components of the mixture. Further Steps are removing

the solvent containing at least one component from the extraction

column, separating solvent from the solvent containing at least

one component by pressure reduction and/or change in temperature,

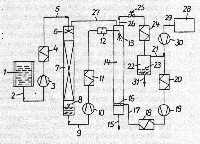

and returning the solvent to the extraction column. The apparatus

comprises an extraction column preceded by a charging column, wherein

the upper portion of the charging column has a mixture inlet, a

solvent inlet, and a liquid distributor, and filler bodies or other

suitable inserts which increase the surface area of the mixture

to be charged.

|

|